RESPETTO

THE PROJECT WAS BORN IN 2019 WITH A CLEAR OBJECTIVE: TO BECOME THE LEADING TECHNOLOGICAL SOLUTION FOR TRANSFORMING INDUSTRIAL AND CIVIL WASTE INTO SECONDARY RAW MATERIALS.

InnovatION ACCELERATORS

We’re able to accelerate the sustainable transition of the fashion and design sectors through the use of an innovative textile waste transformation system with multiple potential applications: from fabric to non-woven.

RESPETTO® MIX

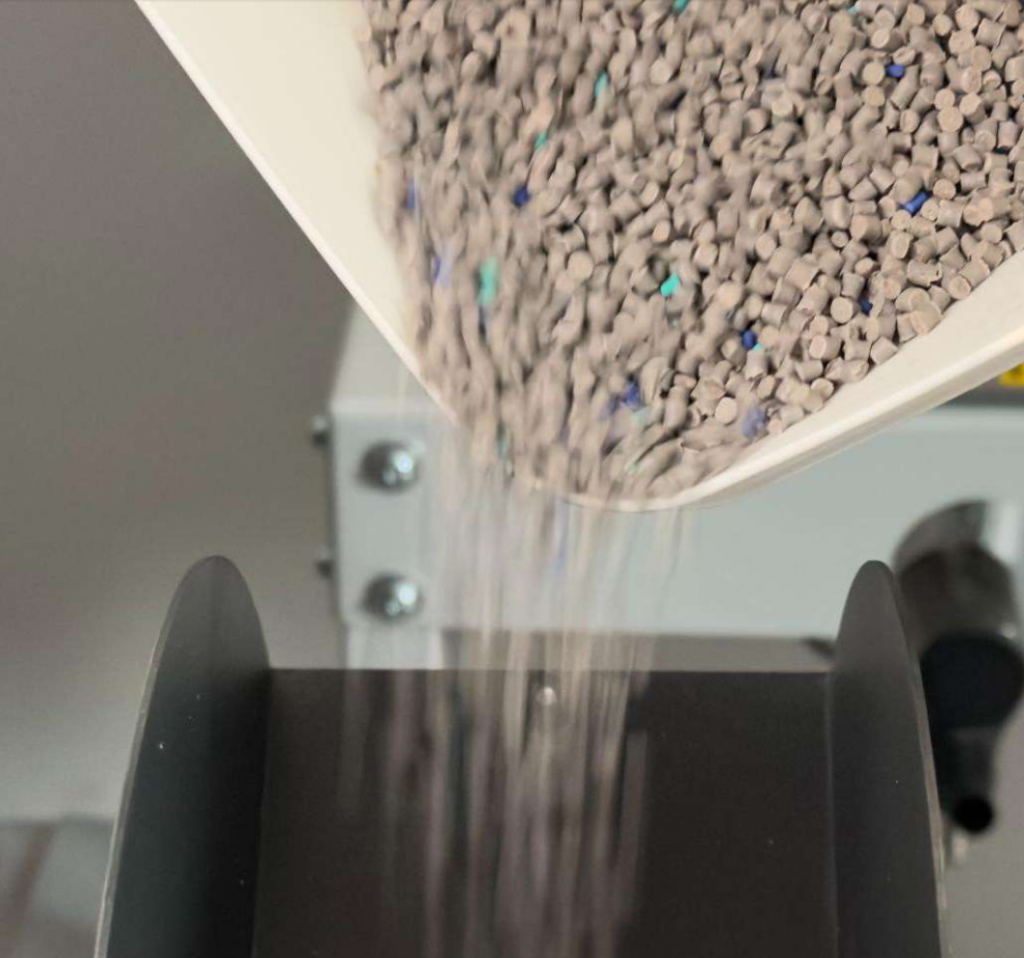

The integrated solution developed combines mechanical recycling, industrial automation and materials technology for the transformation of post-consumer and post-industrial textile waste, thanks to a patented technology in a thermoplastic secondary raw material (MPS) called Respetto® Mix, with different properties depending on the formulation used.

TOGETHER WE MAKE YOUR

COMPANY CIRCULAR

WE HELP YOU MAKE YOUR FASHION OR DESIGN COMPANY SUSTAINABLE BY MAKING YOUR PRODUCTION PROCESS CIRCULAR. WE STAND OUT BECAUSE WE ARE ABLE TO OFFER YOU SOLUTIONS CAPABLE OF MAKING YOU INDEPENDENT IN YOUR TRANSITION.

HOW?

WE REGENERATE YOUR WASTE

Together we study the best approach to recycle and regenerate your waste, creating valuable objects.

WE CLOSE THE LOOP

We offer you the complete system and your personalized Respetto mix, to close the circle in your production of fashion garments.

WHY CHOOSE US?

01 With our plant, 270 tons of textile waste can be transformed per year;

02 The solution is tailored up to 10x, for multi-utility uses;

03 We offer a solution that has the capacity to transform up to 500/1000 kg per hour;

04 The production of the plant is entirely Italian and distributed throughout Europe.

CASE STUDIES

CASSINA

Cassina, founded in Meda in 1927, inaugurated industrial design in Italy in the 1950s according to a totally new logic that marked the transition from artisanal to serial production.

Now, thanks to the collaboration with Regenstech, the company will be able to transform its production waste into new Secondary Raw Material to be used for the production of its collections. For the Salone del Mobile 2024, thanks to the patent we have created a Secondary Raw Material suitable for the production of seat shells with injection molding.

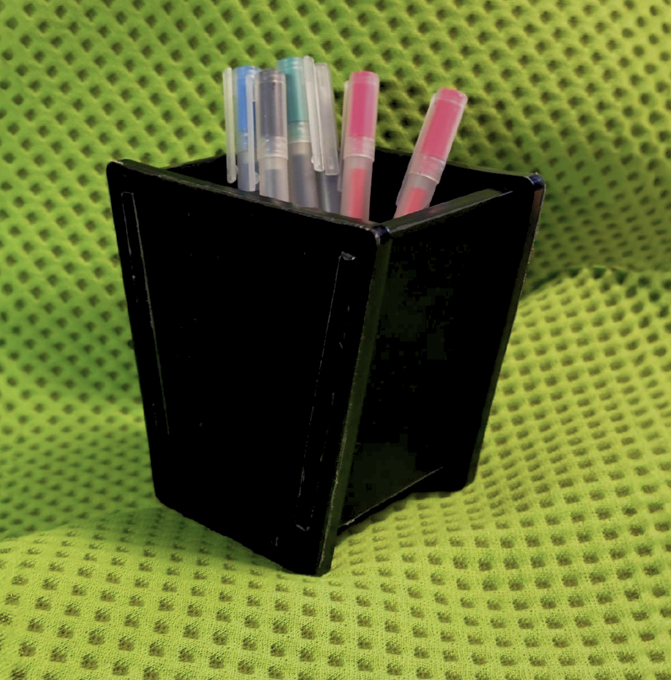

EGO ITALIANO

Regenstech, after 3 years of laboratory tests, began producing objects in thermoplastic material from mixed textile waste using a batch process. An example is the pen holder presented at Design Week 2023 and produced for Egoitaliano, starting from their industrial waste. Thanks to a patented technological process we are able to produce design objects in thermoplastic material (printable) such as pen holders, vases, sales accessories or furnishing accessories starting from mixed fabrics, without the need for pre-selection. From the analysis of the waste, to the creative development of the concept to the production of the objects up to the support on the communication and marketing of the products themselves, Regenesi and Regenstech are committed to completing the entire process and giving communicative value to the project.